Step into the world of PVC foam board, a lightweight, durable, and versatile material that has revolutionized various industries. From eye-catching signage to intricate architectural models, PVC foam board continues to impress with its adaptability and ease of fabrication.

With its unique properties and wide range of applications, PVC foam board has become a preferred choice for designers, builders, and hobbyists alike. Let’s delve into the fascinating world of PVC foam board and explore its remarkable versatility.

Properties and Characteristics

PVC foam board is a versatile material known for its exceptional physical and chemical properties, making it suitable for various applications. Its unique combination of lightweight, durability, and resistance to moisture, chemicals, and UV rays sets it apart from other materials like wood, metal, and acrylic.

The following table provides a comparison of the key properties of PVC foam board with other commonly used materials:

| Property | PVC Foam Board | Wood | Metal | Acrylic |

|---|---|---|---|---|

| Density (kg/m³) | 0.15

PVC foam board is an indispensable material in various industries due to its lightweight and durable properties. However, for applications requiring a finer touch, enstilar foam spray offers an excellent alternative. This sprayable foam provides a precise and controlled application, making it ideal for delicate tasks or intricate designs. Nevertheless, for projects that prioritize rigidity and structural integrity, PVC foam board remains the preferred choice.

|

500

|

2700

|

1180

|

| Tensile Strength (MPa) | 2

|

50

|

100

|

70

|

| Flexural Modulus (GPa) | 0.1

|

10

|

20

|

3

|

| Moisture Absorption (%) | <1 | 5

|

0 | <1 |

| Chemical Resistance | Excellent | Moderate | Good | Excellent |

| UV Resistance | Good | Poor | Excellent | Excellent |

Lightweight

PVC foam board is remarkably lightweight, with a density ranging from 0.15 to 0.45 kg/m³. This property makes it easy to handle, transport, and install, reducing labor costs and enhancing overall efficiency.

Durability

Despite its lightweight, PVC foam board exhibits exceptional durability. It is resistant to impact, scratches, and dents, making it suitable for applications where longevity and resilience are crucial. Its closed-cell structure prevents moisture absorption, protecting it from decay and deterioration.

Resistance to Moisture, Chemicals, and UV Rays, Pvc foam board

PVC foam board possesses excellent resistance to moisture, chemicals, and UV rays. It does not absorb water, making it ideal for outdoor applications or environments with high humidity. Its chemical inertness protects it from corrosion and degradation caused by various substances.

Additionally, its UV resistance prevents discoloration and maintains its aesthetic appeal over time.

Applications and Uses

PVC foam board has gained popularity in various industries due to its unique properties. Its versatility makes it suitable for both indoor and outdoor applications, offering a wide range of uses.

Signage

In the signage industry, PVC foam board is commonly used for outdoor signs, street signs, and billboards. Its lightweight and durable nature allows for easy installation and long-lasting performance, even in harsh weather conditions.

Construction

PVC foam board finds applications in construction as well. It is used for architectural models, where its lightweight and ability to be cut and shaped make it ideal for creating intricate designs. Additionally, it is employed as a core material for sandwich panels, providing insulation and structural support in roofing and wall systems.

Packaging

PVC foam board serves as a protective packaging material for fragile items during transportation. Its cushioning properties and rigidity ensure that products are safeguarded from damage. It is commonly used for packaging electronics, artwork, and other delicate objects.

Displays

PVC foam board is widely utilized in the creation of custom displays for trade shows, exhibitions, and retail environments. Its lightweight and ease of customization make it a versatile choice for eye-catching and informative displays.

Fabrication and Processing

PVC foam board is a versatile material that can be easily fabricated and processed using various techniques. Understanding these techniques allows you to create custom shapes, sizes, and assemblies to meet specific project requirements.

Cutting

Cutting PVC foam board can be done using several tools, including utility knives, circular saws, and CNC routers. The choice of tool depends on the thickness and quantity of material being cut. For thin boards, a sharp utility knife with a new blade is sufficient.

For thicker boards, a circular saw with a fine-toothed blade or a CNC router provides more precision and efficiency.

Step-by-Step Guide to Cutting PVC Foam Board

- Mark the desired cutting line on the foam board using a ruler or measuring tape.

- Secure the foam board firmly to a stable surface using clamps or a vice.

- Hold the cutting tool perpendicular to the foam board surface and apply gentle pressure.

- Cut along the marked line with a steady motion, avoiding sudden movements.

- If using a utility knife, score the surface several times before cutting through the board.

Shaping

PVC foam board can be shaped using various techniques, including sanding, routing, and thermoforming. Sanding can be done manually or with power tools to smooth edges or create curves. Routing can be used to create more complex shapes and designs, while thermoforming allows you to mold the foam board into three-dimensional shapes using heat.

Joining

Joining PVC foam board pieces can be achieved using adhesives, mechanical fasteners, or a combination of both. Adhesives suitable for PVC foam board include contact cement, PVC glue, and double-sided tape. Mechanical fasteners, such as screws or rivets, provide additional strength and durability.When

using adhesives, it is important to apply the adhesive evenly to both surfaces and allow sufficient time for the bond to cure. Mechanical fasteners should be spaced evenly along the joint and countersunk to avoid creating protrusions.

Design Considerations

When designing with PVC foam board, several factors need to be taken into account to ensure optimal performance and aesthetics.

The thickness and density of the board are crucial factors that determine its structural integrity and suitability for specific applications. Surface finish also plays a significant role in both the visual appeal and functionality of the board.

Thickness

The thickness of PVC foam board ranges from 2mm to 25mm, with each thickness offering varying degrees of rigidity and load-bearing capacity.

- Thinner boards (2-6mm) are suitable for lightweight applications such as signage, displays, and packaging.

- Medium-thickness boards (8-12mm) offer a balance between weight and strength, making them ideal for partitions, furniture, and architectural cladding.

- Thicker boards (15-25mm) provide superior strength and are suitable for heavy-duty applications such as construction panels, marine decking, and vehicle bodies.

Density

The density of PVC foam board refers to its weight per unit volume, expressed in kilograms per cubic meter (kg/m³). Higher density boards are more rigid and durable, while lower density boards are lighter and more flexible.

- Low-density boards (300-450 kg/m³) are lightweight and easy to handle, making them suitable for applications where weight is a concern, such as aircraft interiors and boat decks.

- Medium-density boards (450-600 kg/m³) offer a good balance between weight and strength, making them suitable for a wide range of applications, including furniture, displays, and partitions.

- High-density boards (600-900 kg/m³) are extremely rigid and durable, making them ideal for heavy-duty applications such as construction panels and industrial components.

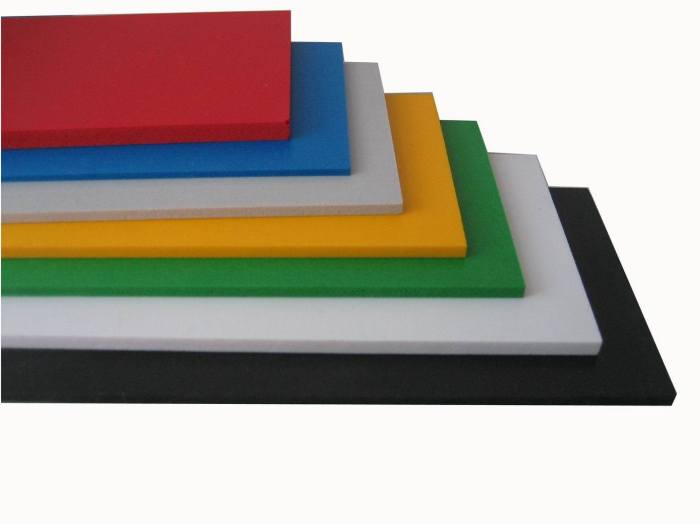

Surface Finish

PVC foam board is available in a variety of surface finishes, each with its own unique aesthetic and functional properties.

- Smooth finish provides a sleek and professional appearance, making it suitable for applications where aesthetics are important, such as signage, displays, and furniture.

- Textured finish offers a more rugged and industrial look, making it ideal for applications where durability is a priority, such as construction panels and outdoor cladding.

- Printable finish is specially designed to accept printing inks, making it suitable for applications where custom graphics and designs are required, such as advertising signs and product packaging.

Environmental Impact and Sustainability: Pvc Foam Board

PVC foam board production and disposal have environmental implications that need consideration. Understanding these impacts and adopting sustainable practices is crucial for responsible usage.

PVC foam board production involves the use of polyvinyl chloride (PVC), a synthetic polymer. The manufacturing process can release volatile organic compounds (VOCs) and other pollutants into the environment. Proper disposal is also essential, as PVC does not biodegrade easily and can accumulate in landfills.

Sustainability Initiatives and Eco-Friendly Alternatives

Efforts are being made to reduce the environmental impact of PVC foam board. Some manufacturers have adopted eco-friendly production methods, such as using recycled materials and minimizing waste.

- Recycled PVC foam board: Made from post-consumer or post-industrial recycled PVC, reducing waste and conserving resources.

- Biodegradable PVC foam board: Formulated with additives that enhance biodegradability, allowing for easier decomposition in landfills.

- Plant-based PVC foam board: Derived from renewable plant sources, offering a more sustainable alternative to traditional PVC.

Responsible Disposal and Recycling Practices

Proper disposal of PVC foam board waste is essential to minimize its environmental impact. Recycling programs exist in many regions, allowing for the recovery and reuse of PVC materials.

- Check for local recycling programs: Contact waste management authorities or recycling centers to determine if PVC foam board is accepted for recycling in your area.

- Separate PVC foam board from other waste: Avoid mixing PVC foam board with other materials to ensure proper recycling.

- Consider waste reduction techniques: Explore ways to minimize PVC foam board usage, such as optimizing cutting patterns or reusing scrap material.

Concluding Remarks

In conclusion, PVC foam board stands out as a remarkable material that combines durability, versatility, and affordability. Its ease of fabrication and adaptability make it an ideal choice for a diverse range of applications, both indoors and outdoors. As technology advances, we can expect even more innovative uses for PVC foam board, further expanding its impact on various industries.

Question Bank

What is the primary advantage of PVC foam board?

Its lightweight, durability, and resistance to moisture, chemicals, and UV rays.

Is PVC foam board suitable for outdoor use?

Yes, it is highly durable and resistant to weathering.

Can PVC foam board be cut and shaped easily?

Yes, it can be cut using a variety of tools, including saws, knives, and lasers.

What is the typical thickness range of PVC foam board?

It typically ranges from 3mm to 19mm, catering to different applications.

Is PVC foam board recyclable?

Yes, it can be recycled, contributing to sustainability efforts.